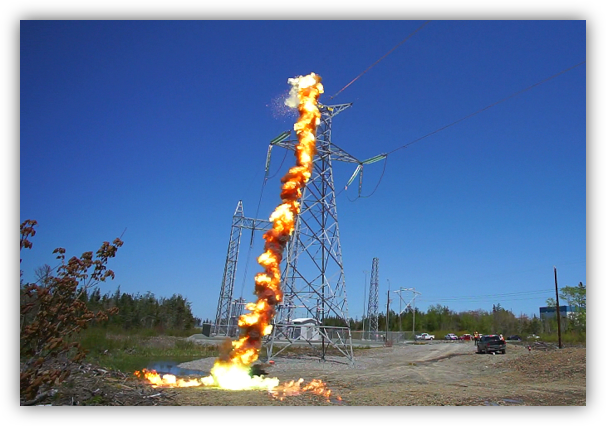

High Voltage DC Line Fault Testing

AeroVision Canada is a leader in HV DC Line Fault Testing, offering unmatched expertise, state-of-the-art technology, and a commitment to client success. With a proven track record and a focus on innovation, AVC is uniquely positioned to meet the needs of utilities seeking safer, more efficient, and cost-effective solutions for fault testing.

HV DC Line Fault Testing is a specialized process used to locate faults in direct current transmission lines. Faults in these lines can result from various causes, such as environmental factors, equipment failures, or physical damage. Traditional methods of fault detection often involve significant manual effort, extended downtime, and high operational costs. HV DC LFL offers a modern, streamlined alternative, reducing these challenges while improving safety and accuracy. This offers multiple benefits:

High Voltage DC Line Fault Testing

Collapsible content

How do drones improve fault testing processes?

Drones allow for safe, efficient, and repeatable fault testing by simulating fault conditions without damaging the primary conductor line.

What are the benefits of drone-induced fault testing?

Include improved safety, reduced operational costs, repeatability, and targeted testing that avoids infrastructure damage.

Which components of utility infrastructure are tested during HV DC LFL?

Components include PC-based master stations, GPS timing units, surge capacitors, wave front detection units, fiber optic communication systems, and more.

Is HV DC LFL suitable for complex installations?

Yes, AVG’s testing solutions are designed for diverse conditions, including complex setups with combined cable and overhead line segments.

Experienced drone line strike operators

As specialists in this field of electrical system testing, AVG has conducted dozens of line strike operations. Components of the Utilities infrastructure that are tested can include: PC computer-based master stations, GPS timing units, Surge capacitor and wave front detection unit electronics, Fiber optical transmitters and receiver communication systems (DC switchyard to the main computer),Optional active detection systems for more complex installations, which include combinations of cable and overhead line segments, and Station-to-station communication system.

The Benefits of Drone-Induced Fault Testing

AeroVision Canada’s proprietary method of drone-induced fault testing offers several significant advantages. Personnel safety is a top priority. By using drones, the need for close physical proximity to high-voltage lines is minimized, reducing the risk of accidents and injuries.The increased standoff distance allows for safer operations, even in challenging or hazardous environments.

Traditional fault testing methods often require extensive personnel deployment and logistical planning. Drone technology significantly reduces these operational costs by streamlining the testing process.The efficiency of drone operations means fewer resources are needed to achieve accurate results.

Repeatability and Precision

Drone technology ensures that line strikes can be conducted with a high degree of repeatability, enabling consistent results across multiple tests.

Targeted strike positions are carefully planned to avoid damage to the primary conductor line while accurately simulating fault conditions.

Operational Flexibility

The ability to perform targeted strikes without damaging infrastructure makes drone-induced fault testing a versatile solution for utilities.This flexibility allows for testing in diverse conditions and across various components of utility infrastructure.

Ready to call in Air Support?

Contact us to learn why AeroVision Canada is trusted by our industry partners and clients.