Electrical Inspections by Drone

AeroVision is transforming the utility industry by providing a safer, more efficient, and cost-effective solution for inspecting power infrastructure.

Drone Inspection Services

Drones, or unmanned aerial systems (UASs), have revolutionized electrical inspections by offering a safer, faster, and more cost-effective alternative to traditional methods like pole climbing or helicopter flyovers. By capturing high-resolution data without putting workers at risk, drone surveying helps utilities improve grid reliability, reduce downtime from equipment failures, and deliver more consistent service to customers.

Electrical Inspections by Drone

Collapsible content

What are the benefits of using drones for electrical inspections?

A safer, faster, and more cost-effective alternative to traditional inspection methods. Our drones conduct high-resolution imaging across vast areas in a fraction of the time, reducing operational risks, cutting inspection costs, and providing the critical data needed to maintain grid reliability.

How do drones improve safety during electrical inspections?

We prioritize safety by using drones to eliminate the need for workers to climb structures or operate heavy machinery near live powerlines. Our aerial inspections drastically reduce exposure to hazardous environments, ensuring safer operations while maintaining inspection precision and speed.

Can drones detect faults in powerlines?

Yes. Specialized drones are equipped with thermal imaging and advanced visual sensors that accurately detect faults such as hot spots, damaged insulators, and energy leaks. Our drone inspection services arm you with data to identify and address critical issues early, preventing costly failures and unplanned outages.

What types of cameras and sensors are used in drone inspections?

Drones used for powerline inspections often feature high-resolution cameras for visual inspections, thermal imaging cameras to detect hot spots, and LiDAR technology for creating accurate 3D models of power infrastructure.

Visual Inspections

Drones equipped with high-resolution cameras provide a detailed view of power infrastructure for excellent visual inspections without the risk of a traditional inspection. This allows inspectors to detect defects or damage to powerlines and equipment that might be difficult or impossible to see from the ground. With drone technology, inspectors can quickly and safely cover large areas of powerlines, which can reduce the time and cost associated with manual inspections.

Thermal Infrared Imaging

Thermal imaging reveals hidden hotspots and energy leaks that aren’t visible to the naked eye. By spotting these signs early, teams can prevent breakdowns, reduce energy waste, and keep systems running smoothly.

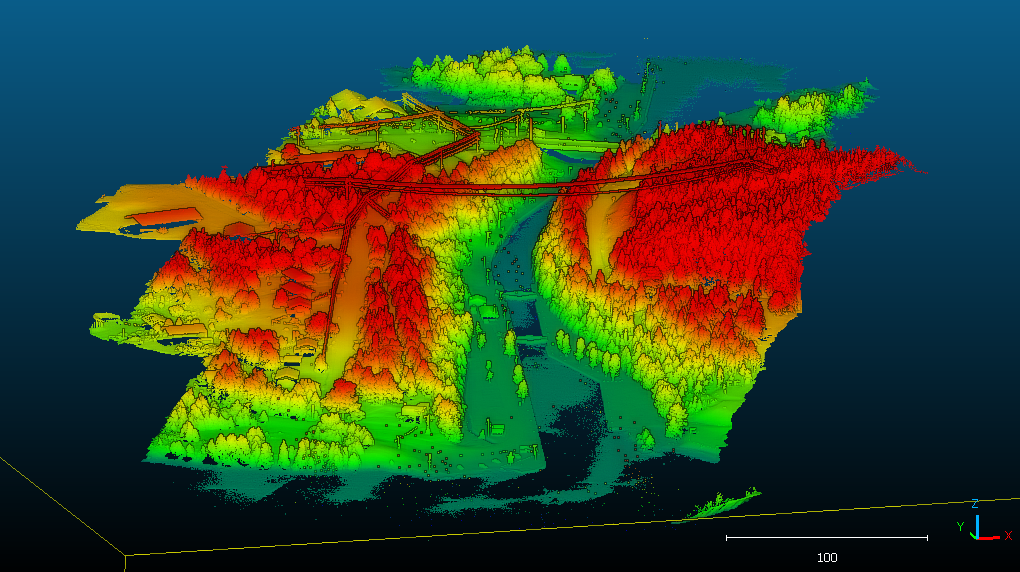

Drone LiDAR Technology

LiDAR scans create precise 3D models of infrastructure like powerlines and towers, making it easier to spot structural issues. With this drone inspection data, teams can plan maintenance more effectively and reduce the risk of unexpected failures.

Improved Process

Drone inspections gather large volumes of data in a single flight, providing a clear picture of asset conditions today and a data-rich foundation for tomorrow. This helps organizations fine-tune their utility inspection strategies and make smarter, faster decisions.

Ready to call in Air Support?

Contact us to learn why AeroVision Canada is trusted by our industry partners and clients.